Besides sorting and sending the next generation of Courier robots?

chinatopwin

chinatopwin

2017-07-27 09:07:11

The development of e-commerce has led to the development of express delivery. In order to

increase the efficiency, China's express industry has also begun to use robots. At present,

most of the functions used by express delivery are sorting and delivery, so what functions will

the next delivery robot have? According to the Wall Street journal, robot developers are already

making breakthroughs in picking and packaging technologies that could be used in future

delivery robots.

For retailers, from shelves to item and pack the goods before delivery to the automation of the

work face huge obstacles, electrical business labor intensive and the work is also one of the

highest part. In most e-commerce distribution centers, picking goods is the most expensive

part of labor costs and one of the least automated processes.

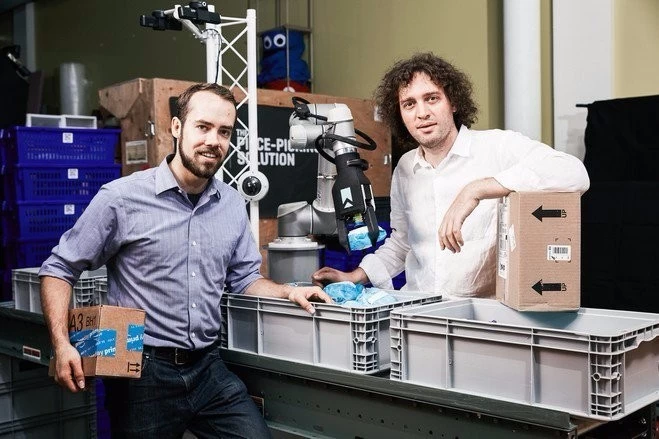

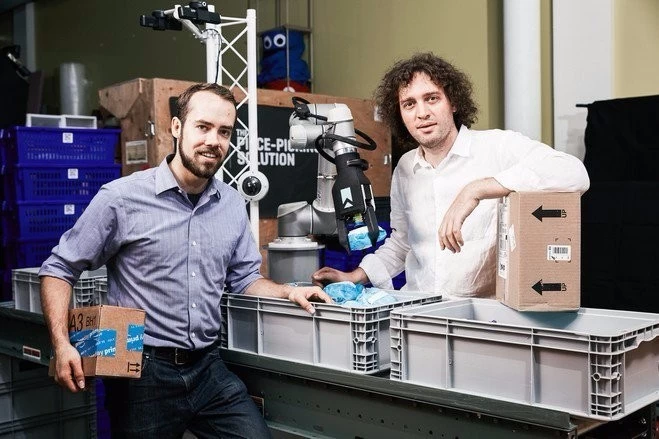

Robot developers, however, has obtained the breakthrough on the technology, including the

Robot developers, however, has obtained the breakthrough on the technology, including the

Saks Fifth Avenue all the Hudson 's Bay and China electricity giant jingdong, several

companies have begun to recent testing of picking robot in the distribution center, according to

some robotics companies, their robots in carrying a small device condition, speed will be faster

than artificial 50%. Jd.com is developing its own pickup robot, which it began testing in April in

Shanghai. Cheng hui, head of jd's silicon valley robotics research center, said the company

hopes to have a fully automated warehouse by the end of next year.

The greatest benefit of a robot to pick up goods is the high yield. RightHand automatic picking

The greatest benefit of a robot to pick up goods is the high yield. RightHand automatic picking

robot Robotics company every time in the process of experiment data records in the related

database, data sets, the greater the mechanical arm picking speed is faster, will also make

reliability. At the same time, because the robot can operate 24 hours, the efficiency is obviously

more than the manpower. And some of the companies hope that through some research into

the open to speed up the development, such as the amazon will later this month in a Japanese

robot technology conference held its third annual automatic picking contest.

But we learned from the news, automatic picking technology into commercial use at least one

But we learned from the news, automatic picking technology into commercial use at least one

year of way to go, the main challenge is to create a huge 3 d draw items database, robots need

these data to determine the best way to grab a new object.